The Economic Impact

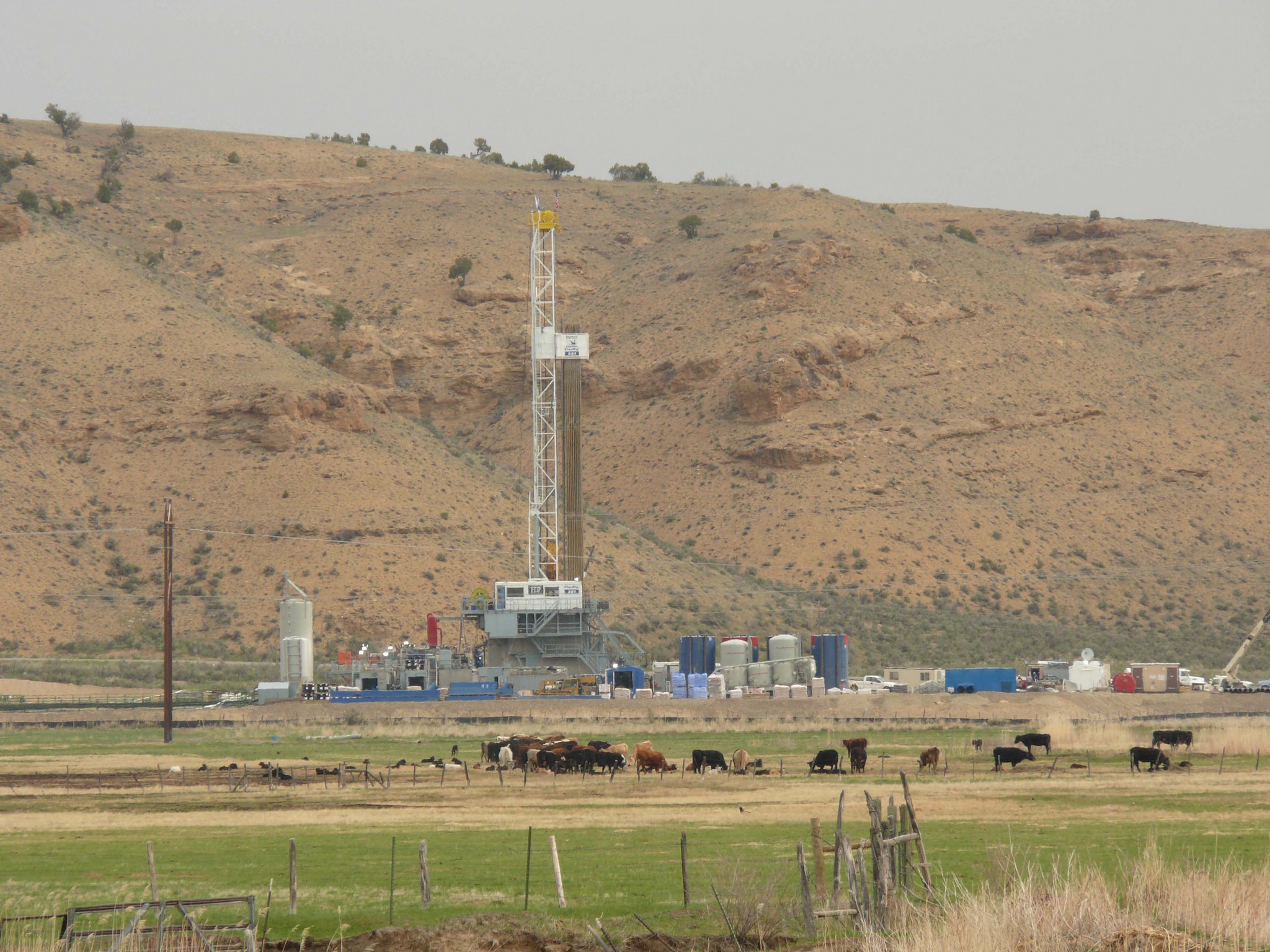

Energy production and extraction obviously have a powerful impact on local economies. For example, the Eagle Ford Shale Formation in southern Texas, after a $30 billion play development in 2013, was responsible for a $60 billion economic impact on south Texas and for 115,000 jobs, all by 2015. However, this benefit has come at a cost. As fracking and renewable energy production has increased, in particular over the last decade, the size and weights of the vehicles and equipment used to haul material in and product out have dramatically increased. Quite literally, it’s a major cause of America’s crumbling infrastructure.

But many of the rural roads that these vehicles are using were not built for such heavy traffic. Many of these roads were built as farm-to-market roads that could handle the occasional large truck. The problem is that increased truck loads do not result in a linear increase in road damage; instead, the impact on pavement increases exponentially compared to rising traffic weights.

For example, in Texas, the legal road limit weight is 80,000 pounds, with a 5% leeway. But that 5% leeway (or 4,000 pounds) does not increase the impact to the asphalt by 5%; rather, it’s closer to 25%. On top of this, some trucks do not keep to a legal limit. So if a 5% increase in weight leads to a 25% increase in road impact, imagine the impact of a 25% increase in load weight.

To put this in perspective, the development of one gas well in particular caused truck traffic equivalent to 8 million cars, with another 2 million cars per year for the life of the well.

A calculation by the Texas Department of Transportation found that it takes 1,184 trucks to get a site up and running, 353 to maintain yearly production and nearly 1,000 for refracturing every 5 years.

The financial impact of this road surface destruction is huge: one 2012 estimate is that it would take $2 billion a year just to get the roads back to their original condition. A 2013 statement from the Texas Department of Transportation estimated that more than $4 billion was needed to maintain its road network. And that didn’t even include expanding it.

Later, TxDOT announced plans to revert many rural roads in south Texas to gravel. Why? Because the costs of repaving the roads was far beyond what the agency could afford.

Advancing Toward a Solution

Another cost of increased trucking is higher numbers of fatal crashes. Between 2009 and 2014, as the fracking industry expanded rapidly in Texas, fatal accidents involving commercial vehicles spiked by 51%.

The same impact has been felt in other states where heavy energy extraction occurs. It began in 2010 in Pennsylvania, as energy companies came in from Texas and Oklahoma. These companies performed as they always had, not taking into account the makeup of the roads in rural Pennsylvania. And, shortly, the roads began crumbling.

The difference between Pennsylvania and Texas is that, in the former, if you pass the weight limit on a posted road, the state holds you accountable for that. Meaning these companies have to pay to repair the roads they damage.

In response, companies have found that the best approach is to upgrade roads in advance of destruction. One engineer from URS Corporation estimates that his company alone built 500 miles of roads across Pennsylvania, Ohio and West Virginia in partnership with the Pennsylvania Department of Transportation and the primary gas and oil companies in the state. “These companies have spent hundreds of millions fixing roads,” he said.

Of course, this impact isn’t just felt by the road agencies and energy companies. Rural communities, and even the broader nation, both directly and indirectly experience a financial cost. First, roads that disintegrate more quickly disrupts connectivity and accessibility to local traffic, who are heavily dependent on these rural roadways to access jobs, education and retail and healthcare facilities.

Second, the same safety issues that pose a risk to commercial traffic impact local and through traffic, potentially even bleeding over to impact local tourism-driven businesses and communities (see the last article in this series for the discussion on tourism).

And third, higher road building, repair and maintenance costs to energy companies get passed on to customers through higher energy costs and reduced profit margins for companies, thereby indirectly impacting job creation.

Balancing America’s Crumbling Infrastructure with the Impact on the Energy Industry

One viable solution to America’s crumbling infrastructure is to downgrade the low-volume, paved roads that are in the worst condition to gravel roads, then use a comprehensive dust control and road stabilization program, converting paved to unpaved roads. This would reduce dangerous road conditions while spreading your road management dollars further to maintain more road miles.

Gravel roads have plenty of their own problems, but a proper dust control and road stabilization program, from a pioneer in the industry like Midwest, can alleviate many of those:

- A 95% reduction in dust makes road networks safer and more accessible (by reducing delays caused by dusty conditions) for moving energy products while reducing the road surface’s impact on the environment.

- By binding dust particles together at the molecular level, Midwest’s proprietary dust control product helps stabilize gravel roads. Road surfaces gain the strength and durability of a paved road, helping them last longer while reducing maintenance.

The energy industry, from extraction to transportation, is literally the fuel that keeps our nation running. Poor rural roadways restrict movement of energy products while increasing costs, both of energy companies and to end consumers. Midwest’s dust control and road stabilization program for exploration and production roads (aka oil and gas pads/roads) can help local road agencies better manage the rural road networks that play a vital role in this industry. It’s just one way Midwest can help solve America’s crumbling infrastructure.