What do roads have to do with the quality of wine you drink? A lot, if you ask one Californian vineyard who recently partnered with Midwest. When this vineyard reached out to us, their current private roads within their ranch weren’t capable of supporting farm equipment and vehicle traffic year-round. They were concerned about the type of product they used and if it was environmentally friendly dust control (unlike chlorides and most other off-the-shelf dust control products). They could not risk ruining their grape vines.

At the same time, the product needed to preserve the natural appearance of the surrounding landscape (unlike lignosulfonates, which leave a black, tar-like substance behind).

They approached Midwest with the objective of creating a stabilized road that could support equipment year-round while meeting the other requirements listed above. So, in the fall of 2018 Midwest technicians installed our NaturalPave stabilization system utilizing our Eco-Pave product. The goal: stronger roads for year-round traffic, and environmentally friendly dust control.

Eco-Pave is an environmentally friendly polymer-enhanced, resin-based organic emulsion that is incorporated into native soils, aggregate or recycled asphalt. When mixed into the top several inches of native soil or aggregate, it creates a durable, resilient surface that can withstand heavy traffic demands. In addition to the superior performance realized with an Eco-Pave stabilized road, the surface keeps its natural, aesthetically pleasing look.

At the vineyard, our technicians blended Eco-Pave into the top four inches of native soil. A seal coat of Eco-pave was topically applied to the stabilized wear course surface to provide additional protection and of course, achieve environmentally friendly dust control.

The results — one year later

One year later, Midwest returned to the vineyard to conduct a geotechnical assessment to evaluate the performance of the Eco-Pave stabilized roads. The objective of this assessment was to confirm the depth of the Eco-Pave stabilization and determine the strength increase achieved in the stabilized layer. Testing was also done as a quality control measure to ensure that heavy rains that the ranch had experienced over the winter of 2018 had not compromised the Eco-Pave stabilization. There had also been some areas that experienced damage after the Eco-Pave installation the previous fall.

To test this, Midwest technicians used Dynamic Cone Penetrometer (DCP) testing. The Dynamic Cone Penetrometer is a portable, hand-held device used to measure the strength and thickness of soil layers. DCP is used worldwide in geotechnical investigations as it is a user-friendly and quick method for evaluating soil and pavement layers. All DCP testing was performed in accordance with ASTM D 6951-03 “Standard Test Method for Use of the Dynamic Cone Penetrometer in Shallow Pavement Applications.”

Soil strength is determined by measuring the penetration of the lower shaft of the DCP into the soil after each time a hammer on the upper shaft drops. The measurement is then converted into California Bearing Ratio (CBR) values. CBR values are a universally accepted strength measurement for soil layers. The stabilized layer will yield significantly higher CBR values than untreated soil, therefore allowing for the identification of different pavement layers.

We conducted DCP testing on 17 areas: 14 were areas where Eco-Pave was installed and three were untreated road surfaces to provide baseline strengths for comparison.

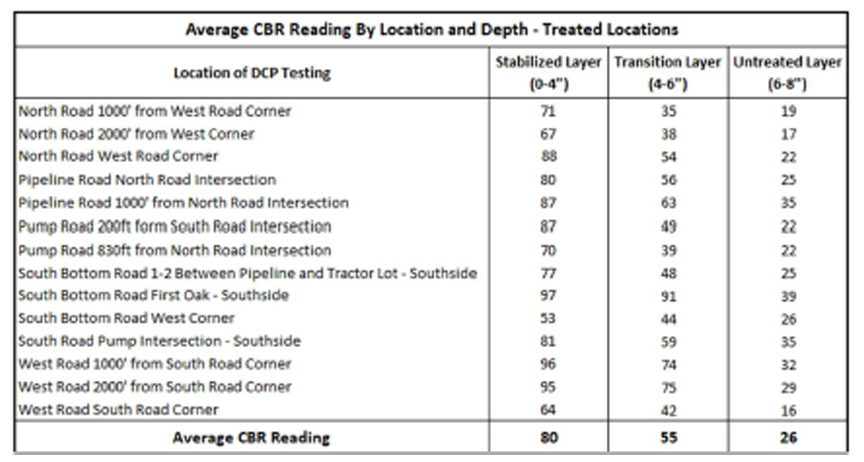

Based on the readings collected, Midwest identified three distinct layers:

- The Eco-Pave stabilized surface layer (from 0-4″ deep)

- The transition layer (between stabilized and untreated layers; from 4-6″ deep)

- The untreated layer/native soil (from 6-8″ deep)

The results of the DCP measurements were that the CBR value of the Eco-Pave stabilized surface layer was 80 compared to a CBR value of 26 for the untreated layer at 6-8″. This is an increase in CBR value of 219%, a whole year after application.

Environmentally friendly dust control based on science, not assumptions

This vineyard now has the benefit of stronger, all-weather roads that can support equipment and vehicle traffic without any risks to vines or the natural beauty of the ranch. And these results are enduring.

Achieving these results required more than just slapping down an off-the-shelf product, though. Midwest’s Eco-Pave product is the result of decades of experience working in every soil type and condition to understand road stabilization and dust control at the molecular level. It’s a scientific dust control program, not an old-fashioned dust suppression method.

Getting the chemistry right is critical. But even more important is the application expertise. Midwest technicians have done this over and over again. They understand all the factors impacting a road stabilization program and know how to customize a plan for each unique site.

Unlike working with other vendors who just sell you a product, this means we can plan and guarantee results. We implement a program that allows you to know in advance what’s going to happen when it’s going to happen and how much it’s going to cost. This offers a level of predictability in your budget that you simply won’t get anywhere else.

And, of course, you get stronger roads that need less maintenance and repairs, more productive access to your area and you know that you’re achieving all of this with an environmentally friendly dust control program.

If you’re still not convinced how this might apply to your own site, consider an initial test. Contact our soil stabilization / dust control experts to receive an assessment and to consider a trial run.