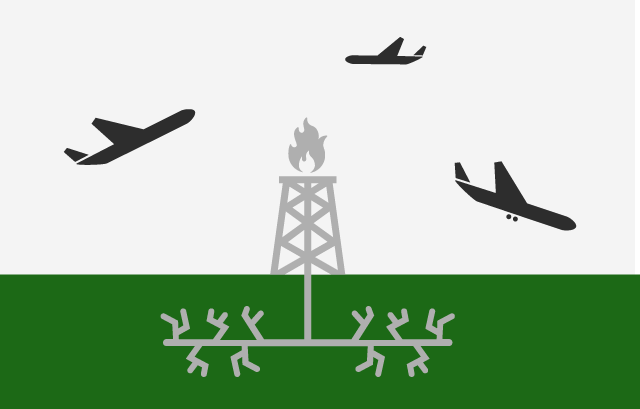

As an increasing number of airports are being explored for gas and oil, measures to ensure safety and environmental challenges are readily available.

Since the early 2000s, the relentless consolidation of the airline industry has had a significant impact on airports all across the country. Dwindling ticket sales have resulted in a wave of mergers and bankruptcies, leaving a number of once-prosperous airports scrambling for ways to supplement their decreasing income.

Pittsburgh International Airport has been hit especially hard by the aviation industry’s decline. According to the New York Times, US Airways phased the airport out as a central hub back in 2004. Since then, flights have plummeted from nearly 600 a day to less than 300.

The Pittsburgh terminal was built to receive 30 million passengers a year, peaking in 1997 at about 21 million. Last year saw less than 8 million passengers, and almost half of the airport’s already-fragile annual budget is spent paying off debt.

Ideal Solution

In recent years, airport and community officials have turned to hydraulic fracturing, or fracking, to balance their books. It just so happens that Pittsburgh International sits atop the Marcellus Shale, one of the most productive oil beds in the world.

As Allegheny County Executive Rich Fitzgerald explains, “It’s like finding money. Suddenly, you’ve got this valuable asset that nobody knew was there.” It’s estimated that gas revenues would provide a $20 million yearly boost, and up to $500 million over the next twenty years, to an airport with an operating budget currently below $91 million a year.

In many ways, airports offer ideal conditions for fracking: they can be accessed easily by a set of drilling pads and deliver resources to one pipeline using a single road.

A company can bore down several thousand feet, then drill lateral wells up to two miles wide beneath thousands of acres of uninhabited land. In other words, airports can facilitate large-scale projects without the usual logistical hassle of securing permission from hundreds of private homes and property owners.

Considering the fact that airports are already so well-suited for drilling, it’s no surprise that many have already turned to oil and gas revenues to supplement their annual income. Dallas-Fort Worth and Denver International have had wells in place for years. According to Fitzgerald, fracking is a means to an end. By lowering costs with shale money, airports will be able to attract more flights and stabilize their revenues.

Taking the Risk Out of Business

Of course, any seemingly perfect solution comes with its drawbacks. Fracking can pose environmental challenges along with a number of logistical complications.

The most effective way to deal with any problem is with a consolidated solution: Midwest Industrial Supply, Inc. is the one-stop-shop when it comes to environmentally-friendly products and logistical support to help minimize ecological impact while increasing efficiency and profit margins.

For example, Midwest provides full-depth reclamation and soil stabilization services, making remote site access easier and safer, as well as lowering maintenance costs. And for dust mitigation on access roads to oil and gas exploration and production sites, Midwest offers a line of highly effective, environmentally-safe products and application programs that eliminate the need for time-consuming and frequent watering.

This approach to dust containment will also help prevent surface deterioration, potholes, and washboarding for as long as the road stays open.

Midwest’s Fines Preservation Program goes beyond simple dust control. Their binder-enhanced synthetic fluid “keeps the road on the road,” preventing particles (also known as fines) from escaping as fugitive dust. The program increases CBR, decreases maintenance frequency, and lowers the life-cycle cost of maintaining access roads.

In sum, Midwest tailors its services to fit the precise needs of any project from start to finish by meeting multi-faceted problems with multi-faceted solutions.