For industrial sites like steel mills, precast operations, mines and quarries who are required to operate with strict air quality permits (Title V Air Quality Permits or OSHA’s Silica Rule), managing respirable, fugitive dust from unpaved areas is a necessary battle. The cost of not implementing a successful industrial dust control program is more than just regulatory fines, though: it includes lost productivity, health concerns for staff and visitors, environmental damage, increased maintenance for roads and unpaved driving areas and more.

The problem in the dust control industry is that many people still treat industrial dust control as an undesirable expense, meaning they shop for the “cheapest” way of getting the job done. But just like with many areas in life, the “cheapest” option is not always the most affordable.

One of the biggest mistakes we’ve seen over decades in the industry is people thinking “product” and not “objectives.” If you buy a cheap product to manage dust at your industrial site, but it doesn’t help you achieve your objectives, or doesn’t help you do so within a reasonable outlay of costs, is it worth it?

Instead, objective-focused thinking means looking at your goals and building a program that helps you meet those goals at the lowest expense possible, beyond just looking for a cheap product.

When treated this way, dust control becomes more of an investment than an expense: it’s used to reduce other management expenses and to increase profitability (by getting rid of logistical bottlenecks created by poor quality dust control programs that reduce production output).

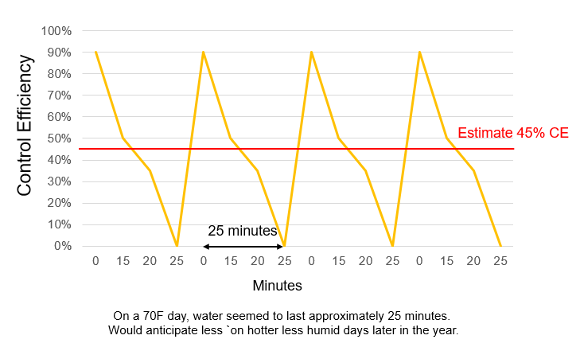

How do you apply objective-focused thinking to your industrial dust control program? With science. Consider something as “free” as water for your dust control program and look what you get:

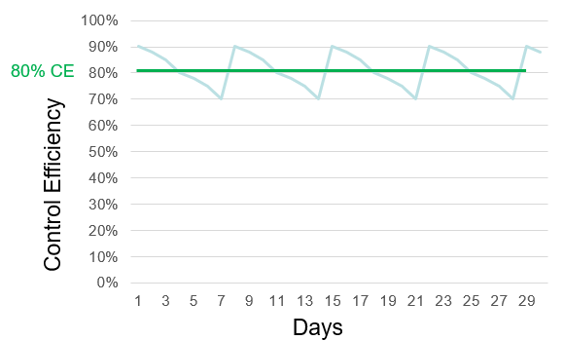

Then consider a program, where application can move from application every 25 minutes to achieve 45% control efficiency, to application beginning with a once per week rate, to eventually months apart achieving 80%+ control efficiency:

Get the Most from Your Industrial Dust Control Program

At Midwest, we’ve been relentless about developing a scientific method for managing dust. We set out with the single goal of helping you achieve those objectives at the lowest cost possible, to the extent that if we don’t think we can deliver you better performance at the best cost, we’ll tell you not to use our products.

Our program is based on science — Dust Control Down to a Science — that is ultimately built around you and your specific site. Your dust control needs, and what it will take to accomplish those objectives, will be different from any other industrial site out there. You need a program customized to you. One that is more than just buying an off-the-shelf product and dumping it on your roadways in the hope it works.

This is how a scientific approach to dust control works.

Program, Not Product

When you are setting out to design a dust control program, there are a few questions to begin with:

- How do you decide which type of strategy will work for your type of operation?

- How do you decide if the cost is acceptable for the performance achieved?

- How do you measure the performance after implementation?

The first question highlights an important principle that many people aren’t aware of: the same strategy and product will work differently in different places. Many factors affect how well a given dust control program works, and these are highly variable. A product that works well in one geography won’t work as well in another. And the product isn’t even 100% responsible for results anyway: in our experience, 60% of the success of any dust control project is the application. The product is only responsible for 40% of the results. (This application expertise comes into play when a facility requires varying levels of product volume and application rates for different surfaces.)

Even within a single facility, road surfaces and fugitive dust levels vary extensively. An industrial dust control program is affected by the local microclimate, the soil quality of road surfaces, the traffic volume, the roadway location (for example, a dump site at the end of a haul road at a mine will likely be a source of dust tracking onto the treated haul road, requiring additional dust control product) and more.

When you come to Midwest to set up a dust control program, we’ll do the investigative work to determine these factors to predict how much product you’ll need and how often it will need to be applied. We’ll also get to know your unique challenges, objectives, and budget. This provides the groundwork for planning your program.

If you’re seeking a “final solution” to your industrial dust control challenges, give Midwest a call. Our Dust Control Down to a Science strategy will save you money on compliance issues, the safety and health of your employees, and the constant challenges dust creates for equipment.