There are many approaches to dust control. From watering to chlorides to lignin sulfonate dust control products, the dust control industry has tried just about everything.

Many companies who have tried off-the-shelf chemicals have been frustrated by the various problems associated with these products. Either the product is toxic for the environment and corrosive to vehicles, like chlorides. Or it doesn’t get lasting results, so must be reapplied, over and over, racking up costs, like lignin sulfonate dust control products. While they are more environmentally friendly than chlorides or petroleum-based chemicals, and they can be temporarily effective, they just don’t last.

An industrial facility that specializes in precast concrete products was experiencing this problem. They had used lignosulfonates for years, but were tired of messing with the sticky, black substance. The site required daily applications, adding on costs:

- The direct cost of the chemical product

- The cost of the water they used to dilute it (especially concerning because it is in a drought-stricken area of the country)

- The extra manhours spent cleaning the lignosulfonate off equipment (it left tar-like stains on anything that touched it)

- The indirect cost of lost productivity as staff had to navigate around tanker trucks daily

Company leadership reached out to Midwest and was excited to find out there’s a far easier and more effective to controlling dust than lignin sulfonate dust control products.

Midwest mixes decades of application experience with cutting-edge technology to control road dust at the molecular level. This provides a much more reliable, scientific method of dust suppression compared to cheap, off-the-shelf products. It also means that we’ve been able to develop a model that allows smaller clients who don’t have the budget to hire us to come in and apply our product to still get these positive results.

Our Guided Self Apply Dust Control program is designed to blend the application expertise of our scientists and technicians with your own team, allowing you to apply our product yourself and know that you will still get the same reliable results is if our experts were on-site. This is exactly what we did for this facility.

From black sludge to elegant solution

The facility required high levels of dust control to comply with local regulations. Given this and the challenges brought on by the approaching rainy season, the program set out to achieve the following:

- Improve the overall environmental health and safety of the site

- Reduce the impact of dust on the air filtration systems of the equipment

- Improve dust control practices with a more efficient chemical and application delivery system

- Eliminate the use of water for dilution and the daily application of black, sticky lignosulfonates

- Reduce the cost of complying with regulations

Our program began with a diagnostic process to allow Midwest technicians to understand the factors affecting the specific location. The site managers filled out a simple questionnaire that allowed our scientists to prescribe the volume and application rate of our product, EnviroKleen.

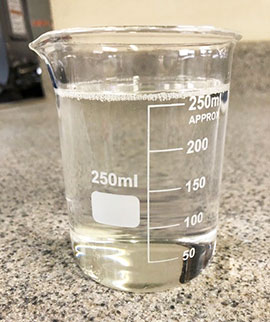

EnviroKleen is a synthetic liquid blended with a bonding agent that ties dust particles together at the molecular level. This serves to keep fines bound together, keeping them on the ground. This network also helps to keep larger aggregates in place, since fines are the “glue” that holds unpaved road surfaces together.

Because of this binding action, EnviroKleen also has an impact on strengthening and stabilizing the surface at a deeper level, creating a more durable, longer-lasting road or pad.

To apply this, we supplied the facility with our custom Portable 1500 Application System, which is a small sprayer that can be transported on the back of a vehicle as small as an F-150 truck. This provides you with complete flexibility in how you apply our product. In this case, we adapted it to go on the back of a flatbed.

Finally, our program also involved initial and ongoing training for the client’s team.

The facility’s application team first applied EnviroKleen on July 12, 2021. Initially, it was believed that nearly two totes (each tote is 275 gallons) would be needed to cover the 54,000 square feet that needed to be treated. However, one tote turned out to be plenty effective.

The application process was so successful that EnviroKleen only needed to be applied once a month, compared to the daily application of lignin sulfonate dust control products. This eliminated the need for tanker trucks, significantly reduced the manpower allocated to dust control, reduced the use of water, freed up space for increased productivity around the site and, of course, completely removed the need for lignosulfonates.

In mid-October 2021, our contact at the facility got back to us to report continued positive results, even throughout recent heavy rainfall.

It’s simply self-application… with guidance. It’s time to switch from lignin sulfonate dust control products to EnviroKleen and the Midwest Guided Self Apply Dust Control Program

Midwest’s program has been proven to get results. It’s an affordable, effective and scientifically driven approach to dust control. If your facility has struggled with dust control, whether due to uncontrolled fugitive dust or to an ineffective approach that may be costing you more than you realize, discover the Midwest Guided Self Apply Dust Control program.