When you think of aircraft, you probably imagine constant take-offs and landings from a concrete or asphalt runway attached to a bustling airport hub. While this scene is most common, there is a good portion of aviation that takes place in the most remote regions. In these private spheres, airplanes are the essential aspect to someone’s survival and the only safe mode of transportation available. This style of flight does not operate on asphalt or concrete and typically the chosen gravel runway solution creates significant problems such as FOD damage.

Where a gravel runway solution can fall short

In order for planes to tackle an environment like a gravel runway, manufacturers provide kits that equip and protect aircraft from the potential damages that can be caused by these small rougher landing strips. These kits include furnishings like abrasion-resistant paint for the wing and fuselage as well as metal shields to guard the brakes and hydraulic tubes.

But many carriers no longer provide these gravel kits for newer models, and beyond that reality, the foreign object debris (FODs) that aircraft are often subject to on a gravel runway solution can still cause immense damage. These damages can cause delays, aircraft changes, and constant maintenance. These physical issues then correspond to startling financial burdens. Repairing FOD abrasion is a large expense, ranging from tens of thousands to millions of dollars. For more information regarding the effects of FODs, you can read our article “How to Reduce Aircraft Damage from Gravel Airstrips”.

Even with the proper landing gear, the runway itself can still pose high risks to your aircraft. As a gravel surface, the fine particles that make it up can become loose over time. As they loosen, bald spots or pitfalls in the surface appear. These areas weaken the internal structure of the runway and destabilize it, and the solutions can be costly with only short-term results.

Midwest’s solution doesn’t start with the plane, but the gravel runway itself.

Midwest Industrial has been providing solutions to dust control and gravel stabilization for over 40 years using the science of chemistry. Within our tenure, we have a long history of servicing unpaved surfaces with a gravel runway solution that works.

When we protect aircraft from FODs and other obstacles with unpaved surfaces, we take a different approach using our SECUR® Gravel Runway Stabilization System. SECUR® delivers a plethora of reasons as to why it should be your solution to strengthening your unpaved runway.

1. SECUR® Stabilization System’s chemical makeup targets every individual particle

The key element of the SECUR® Stabilization System is EK35, a patented synthetic fluid technology. EK35 was crafted using years of research and development to turn into the superior binding agent it represents today. But not only is this chemical effective in eliminating weak spots, repelling water intrusion, as well as its resistance to extreme temperatures as a non-aqueous solution, it’s environmentally friendly, with no concerns of it leaking into the surrounding environment.

2. SECUR® Stabilization System brings layers of protection

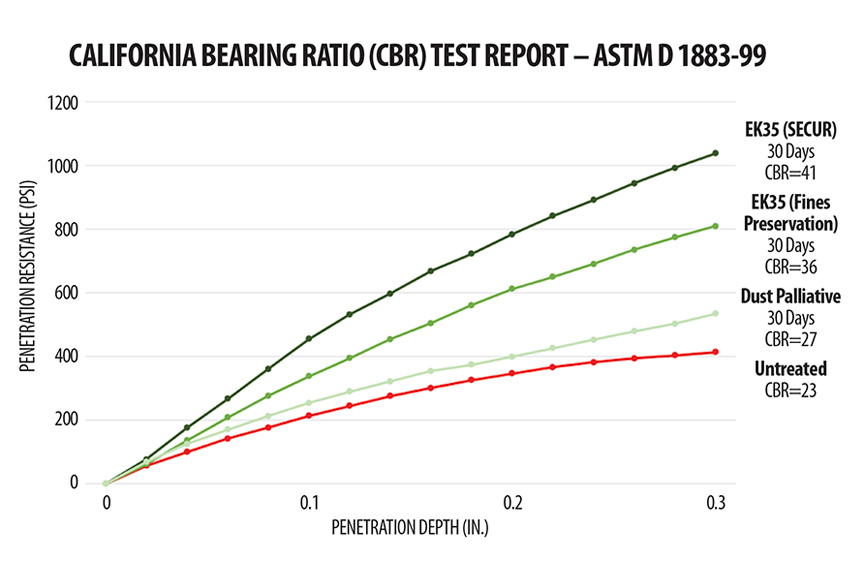

Not only is EK35 an effective component to the SECUR® Stabilization System, it also penetrates deep into the gravel runway to provide rooted protection. When Midwest installs your SECUR® Stabilization System, EK35 is constructed into the top 4-6” of the aggregate surface, creating a hardened runway surface for improved strength, durability, and longevity. After just 30 days, the CBR test report below shows a strength increase from 23 to 41 CBR.

3. Midwest service is always a custom fit

Midwest’s approach to every job is never a one-size-fits all. We work with every client on an individual basis to create a custom plan tailored to your site and its unique condition. Our team will conduct an evaluation of your site, taking soil samples and other measures back to our lab so we can create a custom gravel runway solution that suits your needs. In this sense, we use the same chemistry expertise used to concoct molecular solutions, and go one step further, to fit your scene.

These three reasons are just some of the benefits that come with trusting a company like Midwest to handle your gravel runway solution. With this level of detail and care, we offer a system that will last for years to come. Say goodbye to ineffective fixes, short-term relief, and expensive rounds of reapplication and vehicle repairs. Choose the SECUR® Stabilization System for your long-term needs.

Contact Midwest today to receive a quote or to learn more about the SECUR® Stabilization System