2025 is the 50-Year Anniversary of Midwest Industrial Supply solving complex problems. We’ve engineered a lineup of high-performance products that produce unparalleled results in polymer soil stabilization, dust control, mine tailings management, and more. By harnessing the power of polymer chemistry and its nanotechnology for soil stabilization, Midwest’s solutions are helping a multitude of industries and people live and work better.

While many customers would describe our products as pure magic, we know their key differentiation lies in smarter chemistry and evidence-based science. We believe it takes a molecular approach when it comes to answering the unique challenges particulate matter poses for customers. To showcase its power, we’re breaking down the nanotechnology behind one of our most popular products — Soil Sement® Engineered Formula.

Achieve Stability with Soil Sement®

Before polymer soil stabilization technology, you were typically left with two options for your roads.

- Pave the road with asphalt or concrete, which was costly and often unnecessary for low-volume roads.

- Or use traditional stabilization methods, which are rigid, brittle, and carbon-intensive.

In either case, traditional methods typically are not the ideal and most cost-effective solution for the road— that is, until Midwest developed the Soil Sement Engineered Formula, the engineered polymer emulsion invented to improve the engineering properties and all-weather performance of soils and aggregates.

Midwest’s breakthrough polymer technology creates a dynamic, interlocked matrix that binds road materials to deliver resilient and flexible strength that is freeze-thaw durable, ductile, and environmentally compliant. All this results in better performance at a lower lifecycle cost through reduced material usage and reduced long-term repair and reconstruction expenses.

Unlike traditional methods, this new smart chemistry is rooted in the Midwest’s ultra-long molecular engineered polymer technology that creates long-term structural integrity for stronger, more durable roads that perform under the heaviest loads and harshest conditions.

Polymer Soil Stabilization Under the Microscope

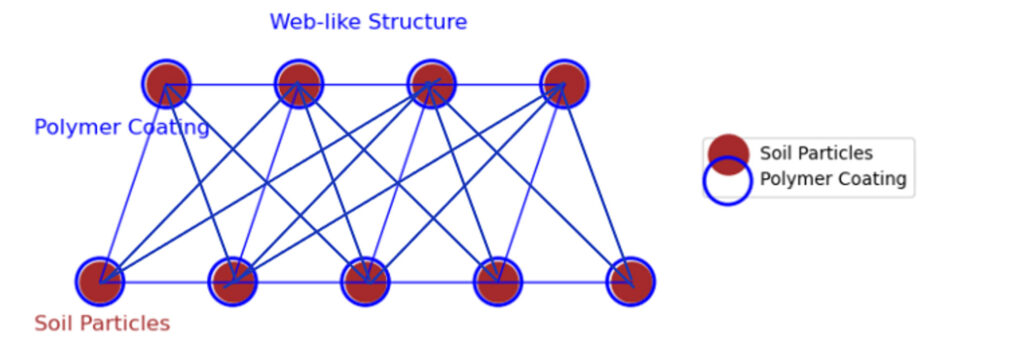

The stabilizer’s nanotechnology attributes are activated as soon as the solution is sprayed thoroughly into the soil or aggregate. The million-molecule polymer chains of Soil Sement create powerful interlocking physical bonds between each soil and aggregate particle, effectively binding them together on a quantum scale.

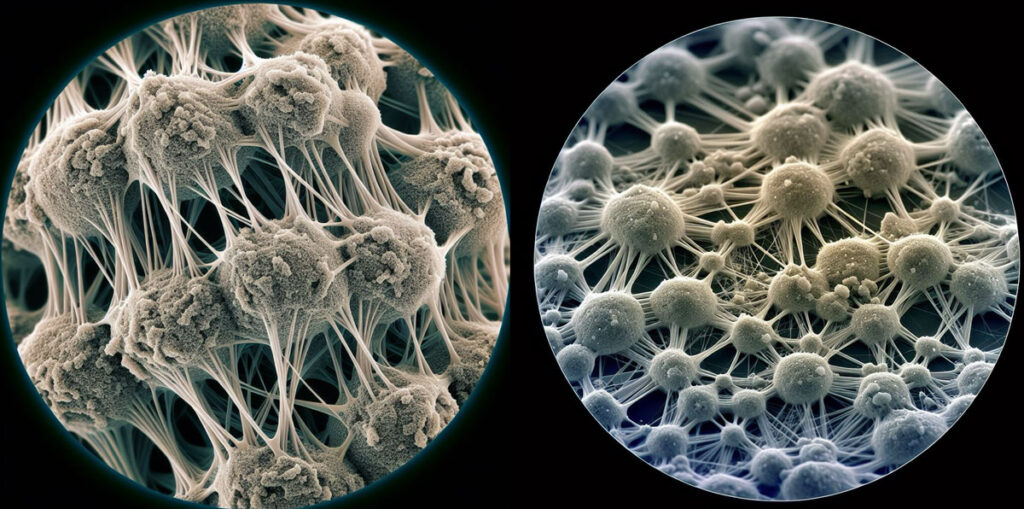

These molecular and extensive polymer chains align in a relatively straight line and then crosslink with powerful force with other chains to form a dense, interconnected, and stabilized matrix. Up to 1 million molecules long, this network keeps soil and aggregate together in a manner that is significantly more resilient, durable, and ductile than traditional stabilization agents, which typically form much smaller molecular chains ranging between 100 and 1,000 molecules.

Together, this system of interconnected polymer chains physically locks the soil and aggregate particles together into a bound matrix.

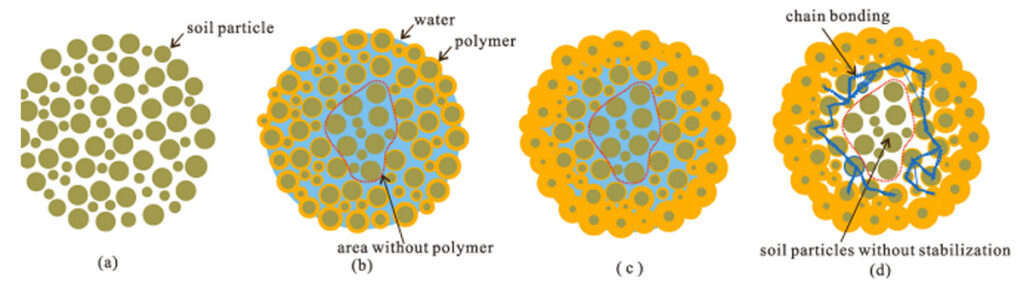

The above graphic depicts these networks of Soil Sement Engineered Formula compared to untreated particles. As the molecules bond with individual soil particles, you’ll notice the distance between polymer molecules closing. The treated particles form one, strong, solid surface, depicted by the closing space between them.

Compare this image to the untreated particles stationed in the center. Unlike the other coated particulate matter, these soil particles lack the reinforcement of the polymer bonding, leaving them more susceptible to displacement.

Small Science, Big Benefits

In its finished state, surfaces stabilized using polymer soil stabilization will experience several noticeable improvements. To start, the network of polymer bonds fortifies your road’s load-bearing capacity as soon as the matrix cures. The heightened durability and strength create a finished surface fit for low-traffic areas or as a solid foundation beneath asphalt and concrete roads servicing high-traffic areas.

As seen above, the unified surface formed by Midwest’s polymer soil-stabilization system provides other protections as well. For example, Soil Sement makes roads resistant to water and moisture, making it a sustainable solution for all weather or seasons. Treated roadways can also resist surface erosion, potholes, deformation, and other forms of road distress. Customers benefit from Soil Sement’s dust-control capabilities, which prevent the road’s critical fine particulate from becoming airborne, protecting workers and residents from the unexpected and harmful fugitive dust emissions.

From an ecological standpoint, Midwest’s polymer soil stabilization solution remains firmly planted on the application site without risk of leaching from the treated area and causing negative impacts to surrounding vegetation and wildlife.

Together, these benefits improve the performance, safety, and longevity of the road at a cheaper lifecycle cost and lower environmental impact than traditional methods. Soil Sement Engineered Formula is the one soil stabilization solution that delivers all of these value-driven advantages. Read our article “Five Soil Stabilization Methods that Address Your #1 Concern” for more information about its benefits.

Midwest’s Polymer Soil Stabilization Solution

Midwest doesn’t engineer polymer soil stabilization solutions like Soil Sement with contingencies. By studying the particulate matter at the microscopic level, we give customers the opportunity to upgrade the strength and stability of their roadways. By doubling down on laboratory research, we’ve developed patented technologies proven to meet the demands of any worksite or situation.

While our approach is rooted in molecular chemistry, our heart lies with helping people work better. From stabilizing aggregate to controlling fine particles, you aren’t just partnering with a team of skilled scientists and engineers, but men and women who are committed to sparking innovations that improve your life and your operation. Contact Midwest today to learn more about the science of polymer soil stabilization.