Midwest was recently invited to a large underground mine in Canada to showcase the efficacy of the MineKleen Plus system in controlling dust levels. The project’s primary objective was to address dust issues in areas currently treated with various products, including leading competitors using base oils, asphalt emulsions, and MgCl. What transpired during our visit was nothing short of exceptional – the trial demonstrated a level of mining dust control that left us astounded, particularly concerning respirable and general dust on road surfaces.

Current State

During our two-day assessment and extensive discussions with the mine’s team, we gained valuable insights into the current dust control measures in place:

| Area | Roads | Ribs |

| Ramps | Asphalt Emulsion / Base Oil | Asphalt Emulsion |

| Levels | Base Oil / Asphalt Emulsion | MgCl |

The asphalt emulsion is applied weekly to the ribs following blasting to mitigate dust generated by these operations. Meanwhile, the base oil is used daily and weekly in high-traffic areas, focusing on intersections. MgCl is applied to the ribs on lower levels and storage areas off the main traffic routes, especially on the roads.

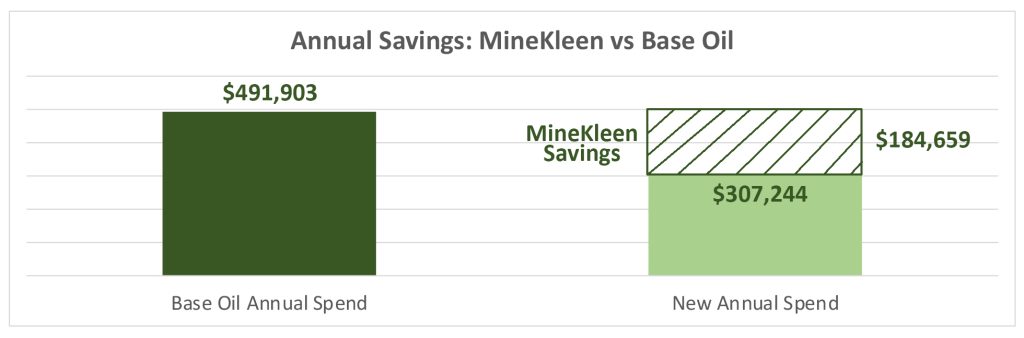

Significant Savings: Competitor’s Base Oil vs. MineKleen Plus

Preliminary trial results conducted by the team indicate a remarkable 60% reduction in the annual MineKleen Plus product requirement to achieve the same level of mining dust control as the leading competitor’s base oil product. Historically, the mine used 1.5 totes of base oil daily for dust control needs. With MineKleen Plus, this usage decreased to 1.5 totes every 2 to 3 days, averaging 2.5 days. This reduction represents a 37.5% decrease in the annual expenditure on base oil, amounting to approximately $184,659 annually. Furthermore, there’s potential for even more significant reductions by optimizing application techniques with the MineKleen Sprayer, provided at no additional cost.

Local Supply

As part of the supply agreement with the mine, OCP would maintain a minimum stock of materials in Sudbury, ensuring on-demand delivery. Should they decide to utilize the MineKleen Sprayer system, spare parts would be readily available, and machine servicing would be provided at no cost.

In conclusion, the mine’s journey with MineKleen Plus marks a significant stride toward more efficient and cost-effective mining dust control solutions, with the potential for substantial savings, and reduced environmental impact. This success story underscores the innovative spirit of the mining industry and the commitment of companies like Midwest to create safer, more sustainable operations.

The Competitive Edge in Mining Dust Control

MineKleen Plus is the go-to choice for efficient and reliable dust suppression in mining operations. Here’s a closer look at why MineKleen Plus is a game-changer:

- Year-Round Storage: MineKleen Plus boasts a lower freeze point, allowing it to be stored outdoors year-round without the risk of freezing or degradation, ensuring it’s always ready when you need it.

- Extended Shelf Life: With a long shelf life, MineKleen Plus remains effective over extended periods, reducing waste and saving costs.

- Ready-to-Use: Unlike some products that require complex dilution or mixing, MineKleen Plus is hassle-free and ready for immediate application.

- Equipment-Friendly: MineKleen Plus won’t stick to vehicles or clog equipment, ensuring uninterrupted mining operations.

- Humidity Resistant: Whether in humid conditions or extremely dry environments, MineKleen Plus performs consistently, maintaining its dust control effectiveness.

- Extreme Temperature Tolerance: It excels in extreme temperatures, ensuring reliable mining dust control even in the harshest climates.

- Continuous Activity: MineKleen Plus remains continuously active, eliminating concerns about drying out and ensuring long-lasting dust suppression.

- Non-Corrosive and Non-Irritating: Its non-corrosive and non-irritating properties make it safe for equipment, the environment, and most importantly, the workforce.

- Waterless, Colorless, and Odorless Application: Applying MineKleen Plus is a seamless process. It’s waterless, leaves no color, and has no odor, making it easy to integrate into your mining operations without disruptions.

These attributes make MineKleen Plus the mining dust control solution of choice for mines looking to maximize safety, efficiency, and cost-effectiveness while meeting regulatory compliance. With MineKleen Plus, you not only achieve superior dust control but also gain a competitive edge in the mining industry.