At Midwest, we’ve been talking a lot about dust control down to a science; that is, using a scientific, data-driven method to fugitive dust control that gets measurable results. This measured approach, in contrast to the traditional haphazard use of dust control products, allows us to set up a program in advance, knowing with a high degree of certainty what the final outcomes will be.

This ability is driven by our philosophy regarding fugitive dust control. We believe that:

- Evaluating your industrial site is critical to understanding the dust sources and challenges in controlling fugitive dust emissions

- Critical knowledge needs to be accumulated to understand traffic flows, traffic loading, spillage, track-on and contamination sources and more

- Products are only 40% of the solution; the other 60% comes from the application strategy

- Product chemistry, soil types and attributes of your industrial site are crucial to product selection based on the site evaluation

Because of these points, at Midwest we don’t just sell a product; we partner with our clients to design programs that take into consideration their specific situation and then track every relevant metric to ensure we deliver the promised results. It’s reliable, it works and we have the data to prove it.

To demonstrate this point, today’s article will focus on two Emission Reduction Programs (ERPs) Midwest recently conducted at two separate sites. The goal of these Emission Reduction Programs are to establish an ongoing work practice standard that sufficiently mitigates industrial fugitive dust emissions utilizing the least amount of dust suppressant chemical possible.

Site #1:

This site faced regulatory compliance issues, where the company was required to keep instantaneous opacity (a measurement of fugitive dust emissions) levels to under 25% on certain roadways and open spaces.

EnviroKleen®, a synthetic fluid and polymer binding system and Midwest’s leading industrial fugitive dust control product, was applied to 15 areas of concern. Overall, an average reduction of over 90% in airborne particulate matter was achieved and maintained throughout the 2019 season. The confidence of this result over the industrial fugitive dust control period was greater than 95%.

(Confidence levels are a function of frequency of application. The less frequent the application, the lower the confidence in the application’s ability to control the emissions over time. Roadway by roadway confidence intervals were calculated based on the greatest length of time between applications. The lowest level of confidence became the overall level of confidence.)

Midwest calculated these results by using two United States Environmental Protection Agency (EPA) methods.

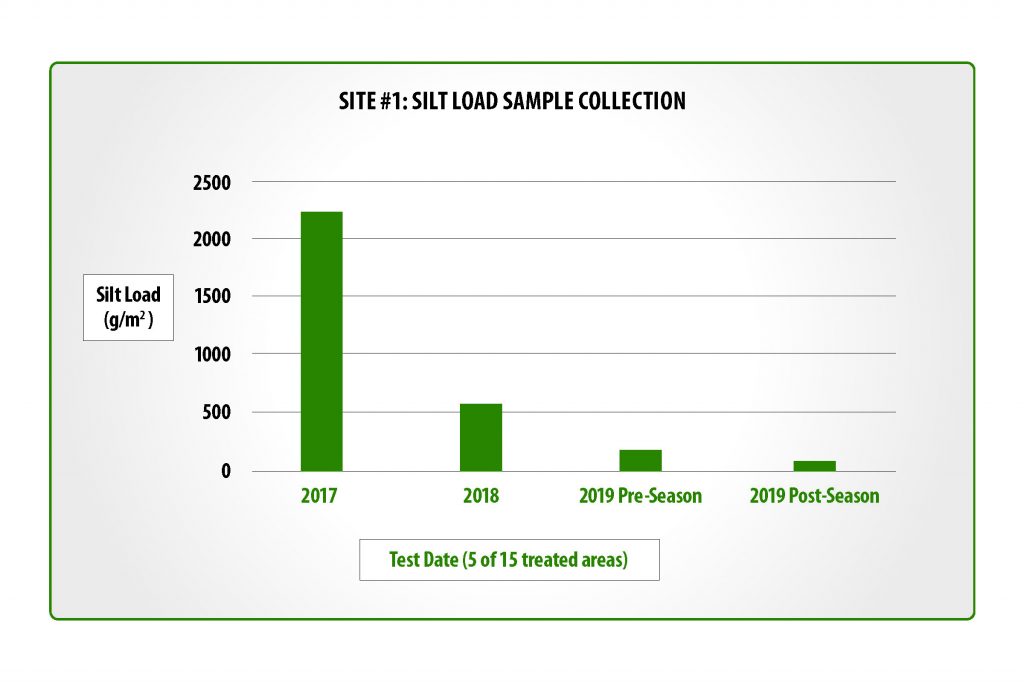

The first is silt load sample collection and testing. This method is used to predict and quantify dust emissions from the resuspension of loose material on the roadway surface due to traffic. Per EPA’s AP-42 document, the term “silt loading” refers to the mass of silt-sized material per unit area of travel (g/m2).

Midwest applied silt load sample collection and testing at five of the 15 treated areas. Samples were collected in 2017 (prior to any fugitive dust control efforts), in 2018, in the 2019 pre-season and in 2019 during and after the application season:

- 2017: 2,231.00 g/m2

- 2018: 582.20 g/m2

- 2019 (pre-season): 160.27 g/m2

- 2019 (post-season): 91.05 g/m2

From 2017, before any dust control measures were applied, to the end of the 2019 season, this equated to a total of a 96% reduction in silt content. (The reduction in levels from year to year showcases the benefit of using an effective fugitive dust control program over time: the dust control product used has a compounding effect, meaning it gets more effective over time and, therefore, requires less product to get the same results in future applications.)

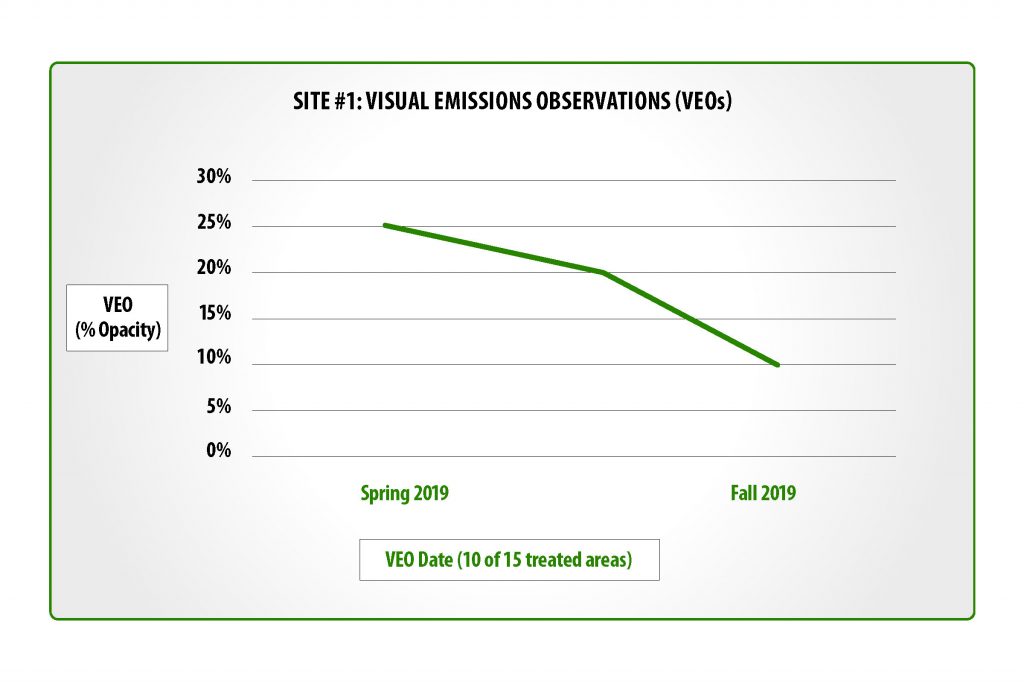

The second method used was Visual Emissions Observation (VEO). This method is based on physically observing emissions levels, as implied by the name, and requires performance by certified observers to adhere to US EPA Method 9. Visual Emissions Observation allows Midwest’s engineers to determine instantaneous opacity levels.

VEOs were conducted at 10 of the 15 sites before and during the 2019 season. Pre-season levels of instantaneous opacity averaged 25%, threatening to push the site into regulatory noncompliance. Before the 2019 season began, Midwest in partnership with this facility set out to achieve a 15% average opacity level. In reality, throughout the season, VEOs conducted on treated areas ranged from 0-25%, with an average opacity of less than 10%.

Using these two methods, we were able to calculate that the Emission Reduction Plan for this industrial facility was successful, achieving an average reduction of over 90% of airborne particulate matter.

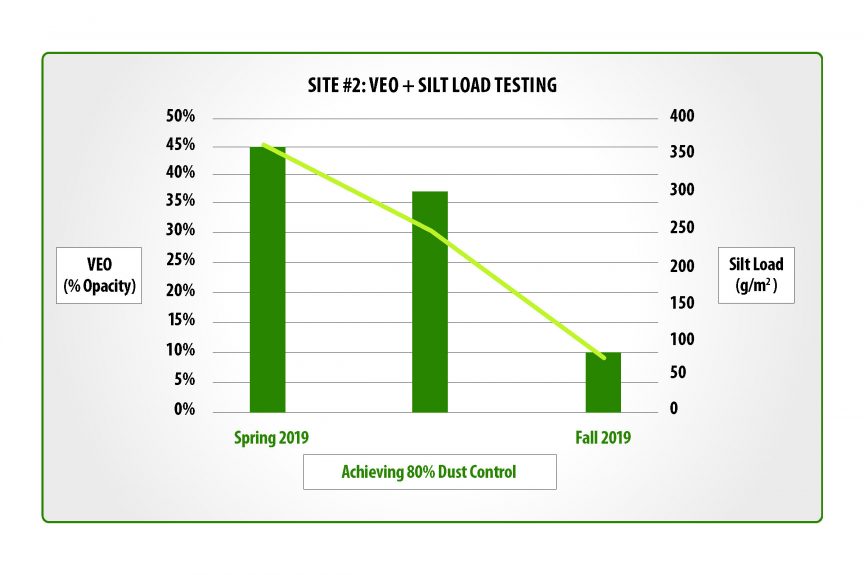

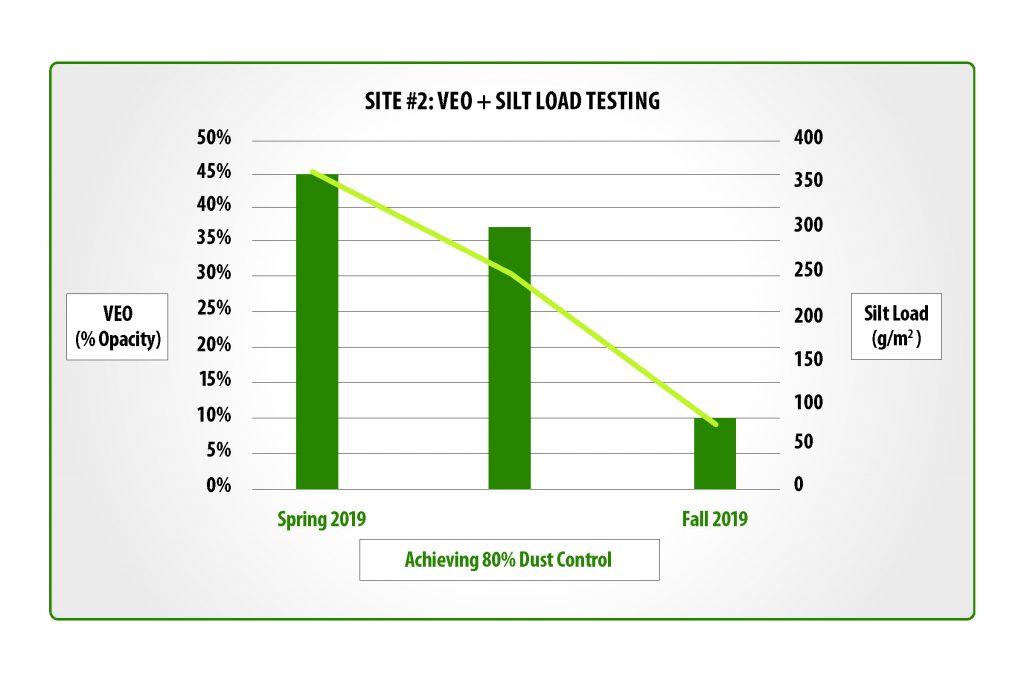

Site #2:

Similar to the previous site, this facility was experiencing uncontrolled levels of fugitive dust emissions. Midwest applied EnviroKleen® to three treatment areas, using the same EPA methods to test before and after application. Unlike the other facility, this was the first occurrence of applying Midwest’s product, as it was a trial period, so there was no cumulative impact of the product on the soil.

(Additionally, a single application means that confidence could not be calculated.)

Pre-season instantaneous opacity readings taken using Visual Emission Observations on unpaved, untreated areas averaged 45%. On treated areas, this average dropped to 10%.

Similarly, pre-season silt levels for untreated surfaces were measured at 360.81 g/m2. After the season, levels on treated surfaces averaged 71.38 g/m2, a reduction of over 80%.

Using these test results, we calculated that the Emission Reduction Plan at this facility successfully achieved a greater than 80% reduction in airborne particulate matter throughout the season.

Fugitive Dust Control Down to a Science

These predictive results are a result of our Dust Control Down to a Science methodologies. We have highlighted similar fugitive dust control plans in the past and invite you to be our next success story!

The key point to take away from these case studies is not just that we achieved the desired results. It’s that we were able to predict those results in advance, by using disciplined data collection and tracking throughout the application process, and because of the application experience of our team of engineers and data scientists.

If you’d like to experience similar fugitive dust control results at your industrial facility, Midwest offers a trial to prove the results we can achieve for you. You can choose whether that trial period should be conducted as a guided self apply dust control program, where you apply the fugitive dust control solution yourself with Midwest supervision, or as a managed service program, where Midwest personnel are onsite for testing and observation, product application and post-application tracking.

Whichever you’d prefer, contact us today to get started.